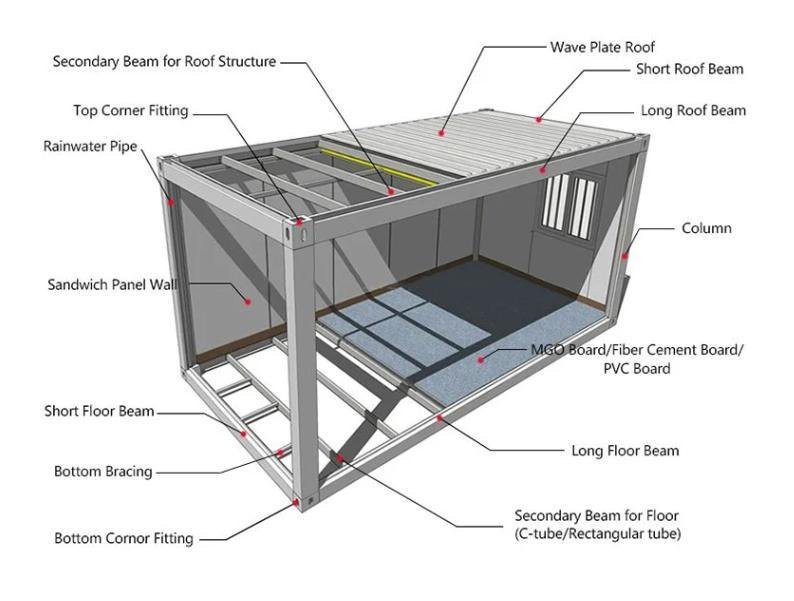

Detachable Container House

| NO. |

| ITEM |

| 1 | STRUCTURE | Column |

| 2 | Upper beams |

| 3 | upper size beams |

| 4 | bottom cross beams |

| 5 | bottom side cross beams |

| 6 | upper corner set |

| 7 | bottom corner set |

| 8 | Hexagon socket bolt |

| 9 | Rubber pad |

| 10 | Auxiliary Section | Bottom bolt |

| 11 | Bottom purlin |

| 12 | downpipe |

| 13 | upper square steel tubes |

| 14 | Maintenance Section | exterior roof tiles |

| 15 | insulation glasswool |

| 16 | moisture sealer |

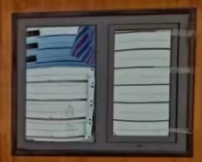

| 17 | MGO floor |

| 18 | with double steel sheets |

| 19 | plastic-steel double glass window |

| 20 | Column corner trimming (with fasteners) |

| 21 | color steel V831 suspended ceiling |

| 22 | angle iron |

| 23 | backwash tank |

| 24 | Drilling tail |

| 25 | Flat head drill tail |

| 26 | structural sealant |

| 27 |

| electricity system |

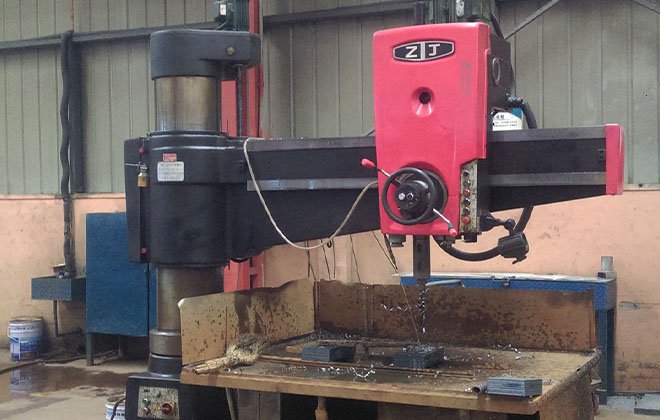

Steel Structure Manufacturing Plant Characteristics:

1. Wide span: single span or multiple spans, the max span is 36m without middle column.

2. Low cost: Unit price range from USD35/m2 to USD70/m2 according to customers' request.

3. Fast construction and easy installation.

4. Long using life. up to 50 years.

5. Easy construction, time-saving, and labor saving

6. Flexible layout, beautiful appearances, and higher space efficiency

7. Be used as warehouses, workshops, shopping mall, dinning hall, stadium, etc.

8. Others: environmental protection, stable structure, earthquake proofing, water proofing, and energy conserving.

How To Build A Prefabricated Steel Structure Warehouse?

You should give us the following data:

1)Design Data

1.live load on roof(KN/M2)

2.wind speed(KM/H)

3.snow load (KG/M2) if have

4.earthquake load if have

5.crane (if have), lift height, lift capacity,

2)Size

1.width

2.length

3.eave height

4.roof slope

3)Type

1.single slope OR double slope

2.muti slope OR single span

3.double-span OR Multi-span

4.single floor OR two floors

4)Intercolumn

5m, or 6m….

5)Windows &Door

1.quantity

2.size

3.Location

4.PVC or aluminum

6)Column &Beam

straight cross-section OR Variable cross-section

7)Roof & Wall Panel

1.colorfull corrugated steel sheet 0.326~0.8mm thick ,YX28-205-820(820mm wide),

2.sandwich panel with EPS,ROCK WOOL,PU etc, insulation thickness around 30 ~300mm,

3.sheet+glass fiber(thick 50mm~200mm)

8)Purlin

1.C purlin size:120~C320,Z

2.purlin size100~Z200

9)Accessories

Do you need the skylight belts, Ventilators, down pipe, out gutter etc?

10)Surface Treatment

Shot blasting with anti rust paint or hot dip galvanize